Surface-EXT® Reinforces Slurry Seal & Micro Surfacing Applications

Why use Surface-EXT® in Slurry and Micro Surfacing?

Glass fibers are the ideal choice for slurry and micro surfacing due to their superior properties. Virtually water neutral, Surface-EXT™ has a specific gravity equal to that of the aggregate. These properties ensure the fiber will disperse evenly with the aggregate in the pug mill and will not clump in the mix or float to the surface as other synthetic fibers may have a tendency to do.

Overview

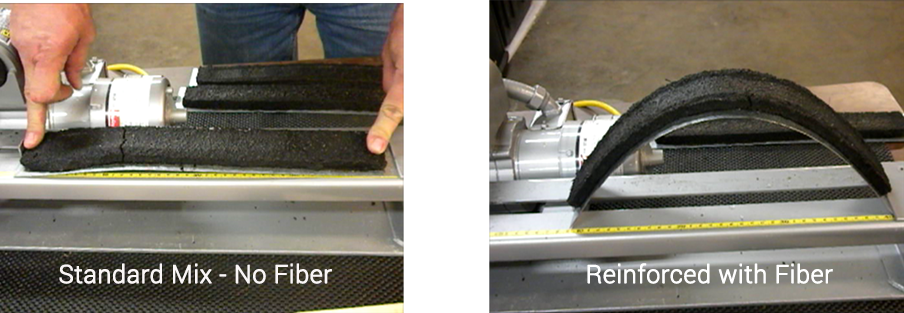

FORTA® Surface-EXT is an alkali and acid resistant glass fiber specifically designed to extend the life of slurry surfacing applications. Surface-EXT improves flexibility and longterm durability. Surface-EXT is extremely easy to use and has a specific gravity similar to that of the aggregate, which allows it to disperse completely and evenly into the slurry mix. The glass fiber can be used at any dosage to suit the end user’s project needs. Surface-EXT does not increase the water demand of the mix and may reduce the setup and cure time of the mix thus reducing overall road closure time.

The goal of Surface-EXT is to increase the durability and life of pavement preservation slurry surfacing by forming a bonding matrix with the asphalt and aggregate which allows energy to disperse more evenly in the cured mixture.

Download Surface-EXT Technical Sheet

Benefits

1. Surface-EXT® is alkali resistant and does not depend on any coating.

2. It is virtually water neutral.

3. Fine individual filaments: a large number of fibers are released when mixed in the pug mill and the filaments do not protrude or have

a negative impact on the surface finish.

3. Have a superior bond (mineral/mineral interface) with the slurry/micro mix.

4. Present no health hazards. Safe and easy to incorporate into the mix. User-friendly.

Flexural Tension Test

Read about a recent project using Surface-EXT here.